Renault Clio: Front side member closure panel, front section: General description

IMPORTANT

Use a repair bench to ensure the positioning of the points and the geometry of the axle assemblies.

Note: The information contained in the following describes the general repair procedure for all vehicles having the same design for this part.

Before reading the following general information, make sure that there are no special notes associated with the vehicle. These special notes are specified if necessary in other parts of the sub-section dealing with the component.

Note: For a detailed description of a particular connection, see MR 400.

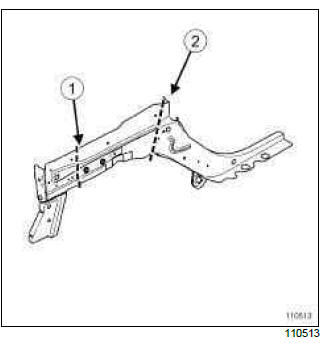

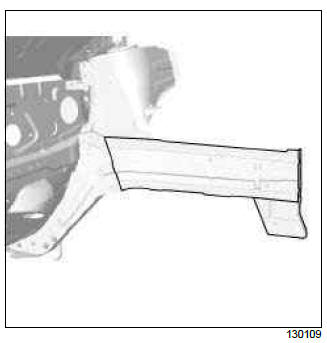

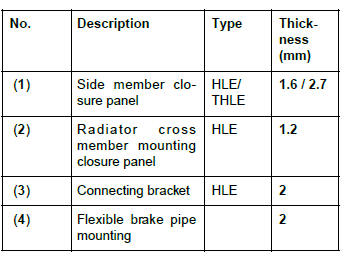

I - DESIGN OF THE STRUCTURAL COMPONENT

The special feature of this type of part is that it combines the functions of both the front section and rear section of the front side member closure panel and that it is made of two different kinds of panels of different thicknesses assembled by laser butt welding.

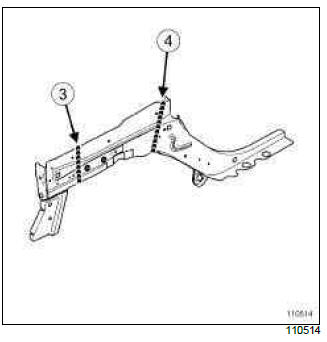

II - AREA TO BE CUT FOR PARTIAL REPLACEMENT

Note: For the partial replacement of parts constituting a single structural component, it is essential to stagger the welds of each of the components.

For removal of the side member (see 41A, Front lower structure, Front side member: Description, 41A-8).

1 - Cut 1: This line shows the centre of the area in which it is possible to carry out a partial replacement.

This operation allows you to access the inside of the hollow section of the structural component to straighten it.

2 - Cut 2: The cut must be made on the splice.

III - ASSEMBLY INSTRUCTIONS FOR A PARTIAL REPLACEMENT

In this case, the side member weld line must be staggered from that of its closure panel.

Note: For the partial replacement of parts constituting a single structural component, it is essential to stagger the welds of each of the components.

Only the connections which are specific to the partial replacement by cutting are indicated.

WARNING

If the mating faces of the parts to be welded are not accessible, make EGW plug welds to replace the original resistance welds (see MR 400).

If there are other issues regarding access to mating faces, the various replacement options are described in the basic instructions for structural bodywork repair (see MR 400).

Lines (3) and (4) on the diagram show a butt weld by continuous EGW welding.

Weld (4) along the butt weld line.

Front side member closure panel, front section: Description

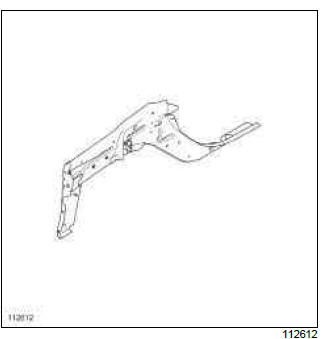

The options for replacing this part are as follows:

- partial replacement of front end section,

- partial replacement of the front section.

IMPORTANT

The straightening bench must be used.

I - COMPOSITION OF THE SPARE PART

II - PART FITTED

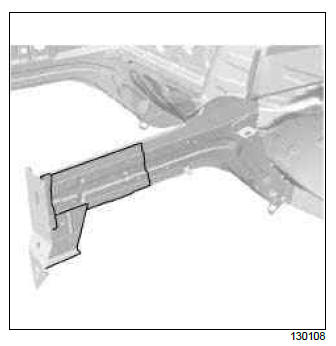

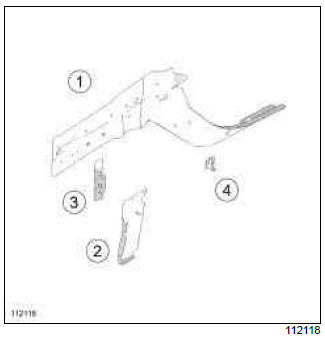

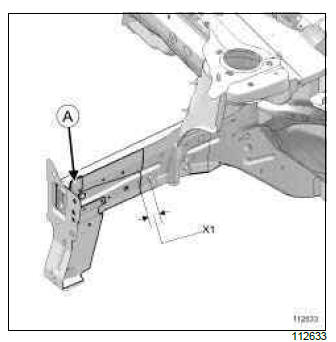

1 - Partial replacement of the front end section

WARNING

Position this part correctly; its position is determined by the position of the inner reinforcements.

(X1) = 40 mm

IMPORTANT

For weld joints in three thicknesses (A), the spot welds on the part replaced should be made in the same place as for the original joint to retain its mechanical properties.

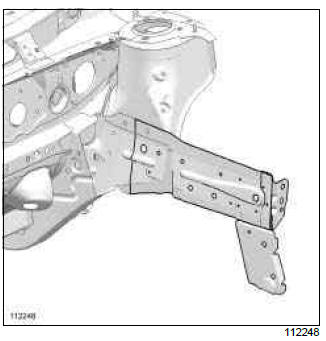

2 - Partial replacement of the front section

To make this cut, first remove the front side member part section along the line of the butt weld.

WARNING

The cut is made along the line of the original butt weld.

Battery tray bracket: General description

Note: The information contained in the following describes the general repair procedure for all vehicles having the same design for this part. Before reading the following general information, make sure that there are no special notes associated with the vehicle. These special notes are specified if necessary in other parts of the sub-section dealing with the component.

Note: For a detailed description of a particular connection, see MR 400.

DESIGN OF THE STRUCTURAL COMPONENT

This part is bolted to the front side member. It is made of plastic. The type of plastic is indicated on the part itself.