Renault Clio: Oil vapour rebreathing circuit: Descriptions

K4J or K4M, and 780 or 800 or 801

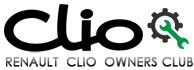

- Oil vapour rebreathing duct

- Calibrated port

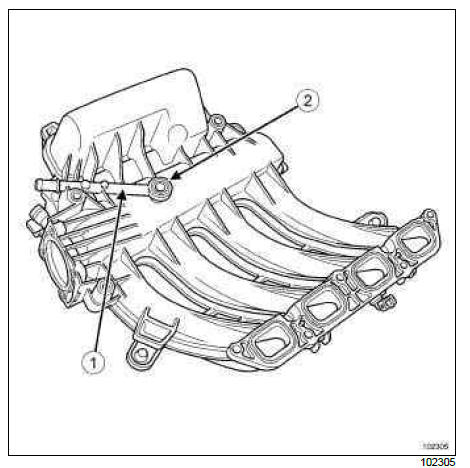

- Oil vapour recovery plate located on the rocker cover

- Oil vapour rebreathing hole

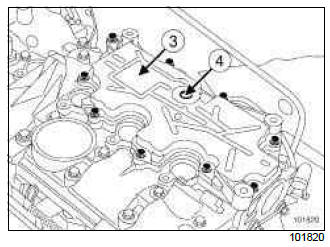

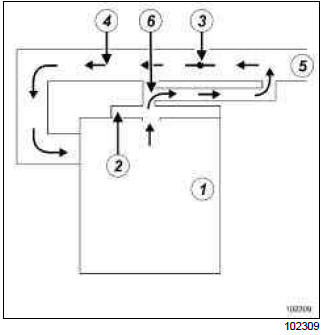

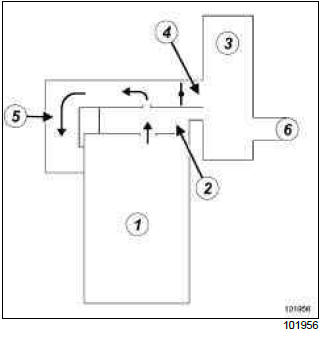

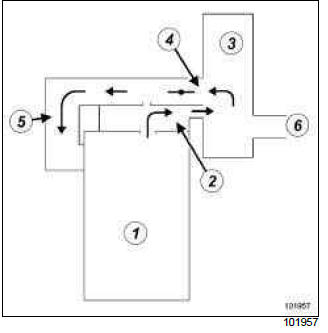

Oil vapour rebreathing circuit: Operating diagram

K4J, and 780 - K4M, and 800 or 801

A: under low loads, the oil vapours are rebreathed in small quantities through the calibrated orifice (6).

B: under medium and heavy loads, the oil vapours are rebreathed in large quantities through the valve

- Engine

- Oil vapour recovery plate

- Motorised throttle valve

- Inlet manifold

- Air inlet

- Calibrated choke

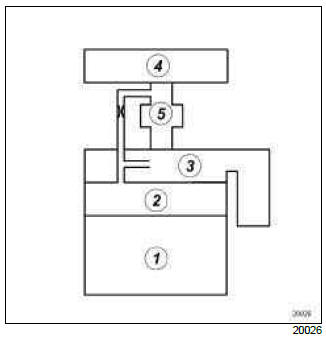

D4F

The oil decanter is located in the rocker cover.

These two components are manufactured together.

- Engine

- Rocker cover

- Inlet manifold

- Air filter unit

- Motorised throttle valve

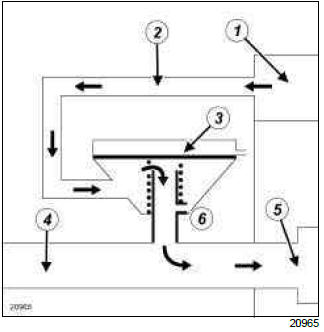

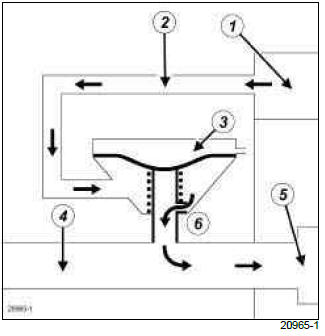

K9K, and 750 or 752 or 764 or 766 or 768

A: Low load

B: Medium and high loads

- Rocker cover

- Oil vapour rebreathing duct

- Oil vapour rebreathing valve

- Air inlet duct

- Turbocharger

- Atmospheric pressure

A: At low load, the vacuum pressure prevailing in the air inlet duct is below the spring calibration. Large quantities of oil vapour are sucked back in by the vacuum prevailing in the air inlet duct.

B: At medium or high load, the vacuum pressure prevailing in the air inlet duct pulls the valve diaphragm, small quantities of oil vapour are rebreathed in via a calibrated jet.

F4R, and 830

Operating diagram of the oil vapour rebreathing circuit for average and high loads

Operating diagram of the oil vapour rebreathing circuit for low loads

- Engine

- Oil separator

- Air filter unit

- Throttle valve

- Inlet manifold

- Air inlet