Renault Clio: Exhaust gas recirculation solenoid valve: Removal - Refitting

K9K, and 764 or 766 or 768

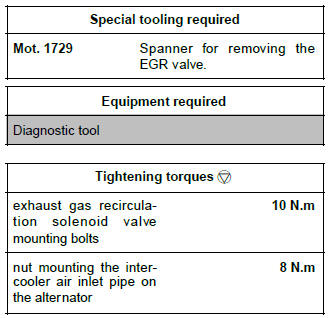

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Disconnect the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

- Remove:

- the engine undertray,

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment).

K9K, and 766 or 768

- Remove the air duct (1) between the intercooler and the turbocharger.

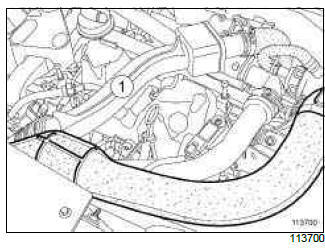

K9K, and 764

- Remove the air duct (2) between the intercooler and the turbocharger.

- Disconnect the oil vapour rebreathing pipe at (3) and move it aside.

II - REMOVAL OF PART CONCERNED

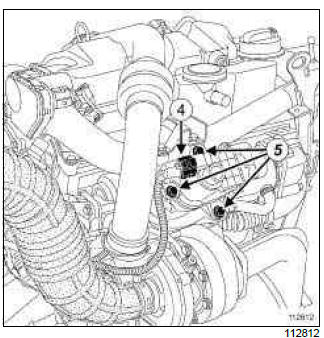

- Disconnect the connector (4) from the exhaust gas recirculation solenoid valve.

- Remove:

- the exhaust gas recirculation solenoid valve mounting bolts (5),

- the exhaust gas recirculation solenoid valve, using the tool (Mot. 1729),

- the seal of the exhaust gas recirculation solenoid valve.

Note: During removal of the solenoid valve using the (Mot. 1729), proceed slowly until the solenoid valve is loosened from its support to remove it.

REFITTING

I - REFITTING PREPARATION OPERATION

- Always replace the seal of the exhaust gas recirculation solenoid valve.

II - REFITTING PART CONCERNED

- Offer up the exhaust gas recirculation solenoid valve with a new seal.

- Torque tighten the exhaust gas recirculation solenoid valve mounting bolts (10 N.m).

III - FINAL OPERATION

K9K, and 764

- Reconnect the oil vapour rebreathing pipe.

- Loosen the mounting nut of the air pipe at the intercooler inlet on the alternator.

- Fit the air duct between the turbocharger and the intercooler air inlet pipe.

- Lock the air duct onto the turbocharger and the intercooler inlet air pipe.

- Tighten the bolt of the air duct on the rocker cover.

- Torque tighten the nut mounting the intercooler air inlet pipe on the alternator (8 N.m).

- Connect the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

Note: If replacing the exhaust gas recirculation solenoid valve, perform the necessary programming (see MR394, Section 13B, Fault finding - Replacement of components).

- Before restarting the engine, use the Diagnostic tool to clear any faults stored by the injection computer.

K9K, and 750 or 752

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Disconnect the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

II - OPERATION FOR REMOVAL OF PART CONCERNED

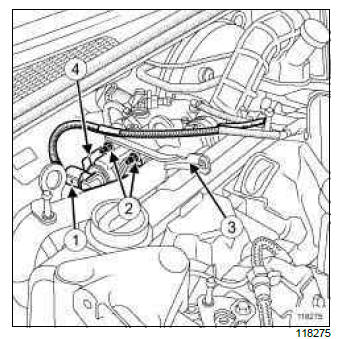

- Disconnect the connector (1) from the EGR solenoid valve.

- Remove:

- the nuts (2) from the strut on the EGR solenoid valve,

- the strut (3) on the EGR solenoid valve,

- the bolt from the EGR solenoid valve heat shield,

- the heat shield (4) from the EGR solenoid valve,

- the EGR solenoid valve,

- the seal between the EGR solenoid valve and the EGR solenoid valve mounting.

Note: Clean the exhaust gas recirculation solenoid valve if it is reinitialised (see Exhaust gas recirculation solenoid valve: Cleaning) (Technical Note 3916A, 14A, Emission control).

REFITTING

I - REFITTING PREPARATION OPERATION

- Always replace the seal between the EGR solenoid valve and the EGR solenoid valve mounting.

II - REFITTING OPERATION FOR PART CONCERNED

- Refit the EGR solenoid valve studs, if necessary.

- Torque tighten the EGR solenoid valve studs (4 N.m), if necessary.

- Refit:

- the seal between the EGR solenoid valve and the EGR solenoid valve mounting,

- the EGR solenoid valve,

- the EGR solenoid valve heat shield,

- the bolt from the EGR solenoid valve heat shield,

- the strut on the EGR solenoid valve,

- the nuts from the strut on the EGR solenoid valve,

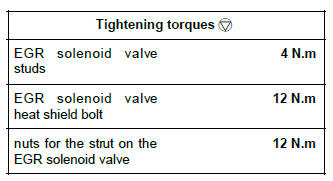

- Torque tighten:

- the EGR solenoid valve heat shield bolt (12 N.m),

- the nuts for the strut on the EGR solenoid valve (12 N.m).

- Connect the EGR solenoid valve connector.

III - FINAL OPERATION

- Connect the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

Note: If replacing the exhaust gas recirculation solenoid valve, perform the necessary programming (see MR394, Section 13B, Fault finding - Replacement of components).