Renault Clio: K4M, and DP0

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

IMPORTANT

During this operation, secure the vehicle to the lift with a strap to prevent it from becoming unbalanced.

- To fit the strap to the vehicle (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Remove:

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the battery tray (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the air inlet duct,

- the air filter box (see 12A, Fuel mixture, Air filter unit: Removal - Refitting, 12A-17),

- the front wheels (see Wheel: Removal - Refitting) (MR 392, 35A, Wheels and tyres),

- the front wheel arch liners (see Front wheel arch liner: Removal - Refitting) (MR 393, 55A, Exterior protection),

- the front bumper (see Front bumper: Removal - Refitting) (MR 393, 55A, Exterior protection).

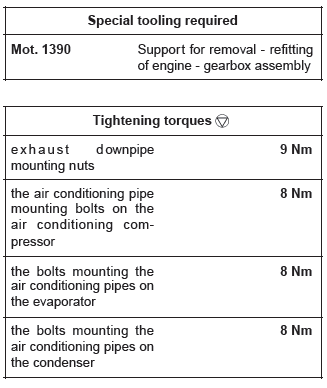

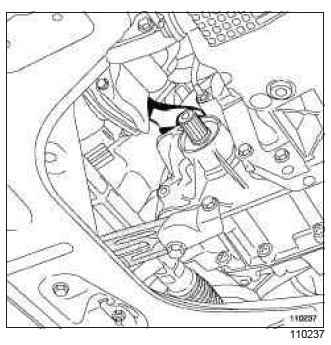

- Disconnect:

- the modular connector (1) by pulling the slide (2),

- the petrol vapour rebreathing pipe on the petrol vapour rebreathing solenoid valve.

- Drain:

- the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16),

- the automatic transmission (see Automatic gearbox oil: Draining - Filling) (MR 392, 23A, Automatic transmission).

AIR CONDITIONING

- Drain the refrigerant circuit (see Refrigerant circuit: Draining - Filling) (MR 392, 62A, Air conditioning).

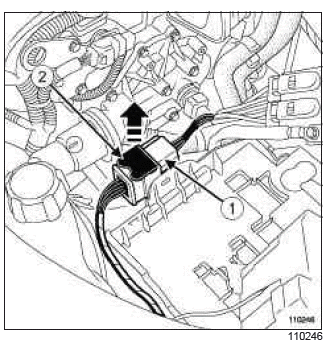

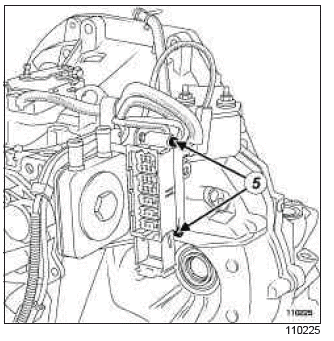

- Disconnect the connectors from the modular connector by pulling the slide (4).

- Remove the modular connector mounting bolts (5).

- Protect the modular connector by putting it into a waterproof plastic bag.

- Disconnect the automatic transmission cooling hoses.

- Remove:

- the " left-hand driveshaft-stub axle carrier " assembly (see Hub carrier - driveshaft assembly: Removal - Refitting) (MR 392, 31A, Front axle component),

- the " right-hand driveshaft-stub axle carrier " assembly (see Hub carrier - driveshaft assembly: Removal - Refitting) (MR 392, 31A, Front axle component).

- Attach the cooling radiator assembly to the front end panel.

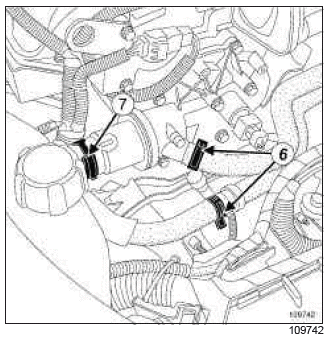

- Disconnect:

- the engine cooling fan assembly connectors,

- the top hose (7) on the cylinder head coolant pipe housing outlet,

- the passenger compartment heating hoses (6).

- Remove:

- the expansion bottle (see 19A, Cooling, Expansion bottle: Removal - Refitting, 19A-101),

- the air resonator (see 12A, Fuel mixture, Air resonator: Removal - Refitting, 12A-10).

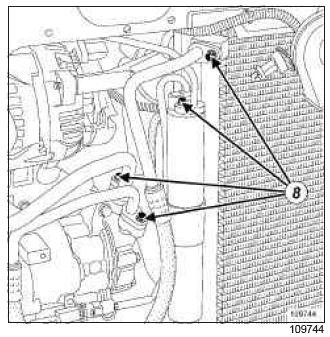

AIR CONDITIONING

- Disconnect:

- the pressure switch from the condenser,

- the mounting bolts (8) from the air conditioning pipes on the air conditioning compressor, on the evaporator, and on the condenser.

WARNING

Fit plugs into the openings.

Plugs must be fitted on the hoses to prevent moisture from entering the system.

- Remove:

- the radiator mounting cross member (see Radiator mounting cross member: Removal - Refitting) (MR 393, 41A, Front lower structure),

- the radiator (see 19A, Cooling, Cooling radiator: Removal - Refitting, 19A-20).

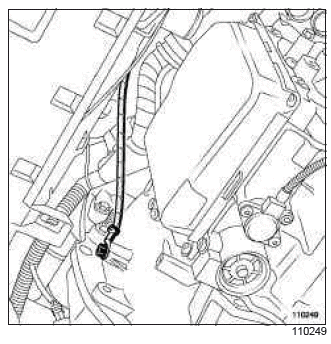

- Remove the earth strap from the gearbox.

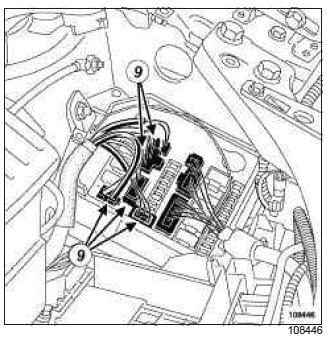

- Remove the Protection and Switching Unit cover.

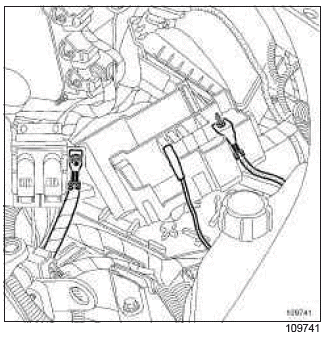

- Disconnect:

- the Protection and Switching Unit connectors (9),

- the brake servo pipe,

- the oxygen sensor connectors,

- the petrol vapour rebreather connector,

- the connector from the lifting eye at the flywheel end,

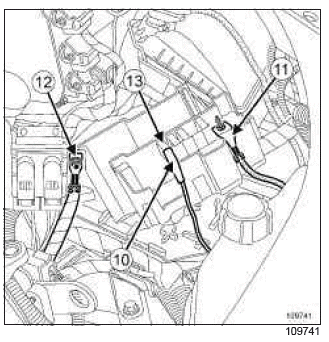

- Disconnect:

- the fuse (10),

- the fuse holder (11) from the fuse board,

- the feed wire (12) from the fuse board,

- the feed wire (13) from the battery protection fuse box,

- the earths on the side member.

- Remove:

- the computer (see 17B, Petrol injection, Petrol injection computer: Removal - Refitting, 17B-37),

- the computer mounting.

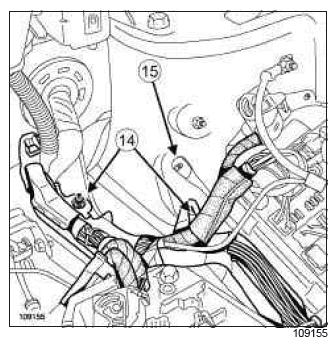

- Remove:

- the wiring harness channel mounting bolts (14) on the body,

- the earth (15).

- Remove the adhesive tape from the electrical wiring harness.

- Disconnect the fuel supply pipe from the injection rail.

- Remove the wiring duct.

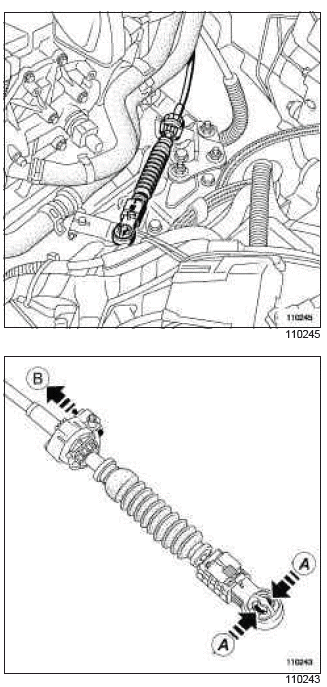

- Remove:

- the gear control cable on the box by pushing in (A),

- the control cable by pushing in (B),

- the wiring harness channel mountings on the gearbox.

- Remove:

- the rear suspended engine mounting (see 19D, Engine mounting, Lower engine tie-bar: Removal - Refitting, 19D-13),

- the exhaust downpipe mountings.

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Mark the positions of the suspended engine mountings on the body.

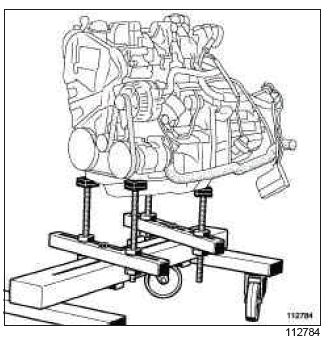

- Support the " engine-gearbox assembly " on the (Mot. 1390).

- Remove:

- the right-hand suspended engine mounting (see 19D, Engine mounting, Right-hand suspended engine mounting: Removal - Refitting, 19D-22),

- the left-hand suspended engine mounting nut (see 19D, Engine mounting, Left-hand suspended engine mounting: Removal - Refitting, 19D-34).

- Strike the stud with a copper hammer.

- Remove:

- the gearbox mounting rubber pad,

- the left-hand suspended engine mounting.

- Raise the vehicle, moving the engine towards the front.

- Be sure to replace the clip on the automatic transmission control cable each time it is removed.

REFITTING

I - REFITTING PREPARATION OPERATION

- For standard engine replacements (see ) (Technical Note 3784A, 10A, Engine and peripherals).

II - REFITTING OPERATION FOR PART CONCERNED

- Position the " engine-gearbox " assembly in the vehicle.

- Refit:

- the left-hand suspended engine mounting (see 19D, Engine mounting, Left-hand suspended engine mounting: Removal - Refitting, 19D-34),

- the right-hand suspended engine mounting (see 19D, Engine mounting, Right-hand suspended engine mounting: Removal - Refitting, 19D-22).

- Remove the (Mot. 1390) from the " engine - gearbox " assembly.

III - FINAL OPERATION.

- Refit the exhaust downpipe mountings.

- Torque tighten the exhaust downpipe mounting nuts (9 Nm).

- Refit the rear engine tie-bar (see 19D, Engine mounting, Lower engine tie-bar: Removal - Refitting, 19D-13).

- Refit the wiring harness channel to the gearbox.

- Refit the gearbox control cable.

- Reconnect the petrol supply pipe to the injector rail.

- Refit the wiring harness channel mountings to the body.

- Refit:

- the wiring harness channel mounting nuts on the body,

- the computer (see 17B, Petrol injection, Petrol injection computer: Removal - Refitting, 17B-37).

- Connect:

- the supply cable to the battery protection fuse box,

- the supply cable on the fuse board,

- the fuse holder on the fuse board,

- the fuse,

- the connector on the lifting eye at the flywheel end,

- the petrol vapour rebreather connector,

- the oxygen sensor connectors,

- the brake servo pipe,

- the Protection and Switching Unit connectors.

- Refit:

- the Protection and Switching Unit cover,

- the earths,

- the cooling radiator assembly (see 19A, Cooling, Cooling radiator: Removal - Refitting, 19A- 20),

- the radiator mounting cross member (see Radiator mounting cross member: Removal - Refitting) (MR 393, 41A, Front lower structure).

AIR CONDITIONING

- Refit:

- the bolts mounting the air conditioning pipes on the air conditioning compressor,

- the bolts mounting for the air conditioning pipes on the evaporator,

- the bolts mounting the air conditioning pipe on the condenser.

Torque tighten:

- the air conditioning pipe mounting bolts on the air conditioning compressor (8 Nm),

- the bolts mounting the air conditioning pipes on the evaporator (8 Nm),

- the bolts mounting the air conditioning pipes on the condenser (8 Nm).

- Connect the pressure switch connector to the condenser.

- Refit:

- the resonator (see 12A, Fuel mixture, Air resonator: Removal - Refitting, 12A-10),

- the expansion bottle (see 19A, Cooling, Expansion bottle: Removal - Refitting, 19A-101).

- Connect:

- the passenger compartment heater hoses,

- the top hose on the cylinder head coolant outlet unit,

- the fan assembly connectors.

- Refit:

- the " right-hand driveshaft-stub axle carrier " assembly (see Hub carrier - driveshaft assembly: Removal - Refitting) (MR 392, 31A, Front axle component),

- the " left-hand driveshaft-stub axle carrier " assembly (see Hub carrier - driveshaft assembly: Removal - Refitting) (MR 392, 31A, Front axle component).

- Connect the automatic transmission cooling hoses.

- Remove the waterproof plastic bag from the modular connector.

- Refit the mounting bolts to the modular connector.

- Connect the connectors to the modular connector.

- Refit:

- the front bumper (see Front bumper: Removal - Refitting) (MR 393, 55A, Exterior protection),

- the front wheel arch liners (see Front wheel arch liner: Removal - Refitting) (MR 393, 55A, Exterior protection),

- the front wheels (see Wheel: Removal - Refitting) (MR 392, 35A, Wheels and tyres).

- Refill:

- the engine if necessary (see 10A, Engine and cylinder block assembly, Engine oil: Draining - Refilling, 10A-12),

- the automatic transmission (see Automatic gearbox oil: Draining - Filling) (MR 392, 23A, Automatic transmission),

- the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16).

- Refit:

- the air filter box (see 12A, Fuel mixture, Air filter unit: Removal - Refitting, 12A-17),

- the air inlet duct,

- the two air inlet duct clips,

- the battery tray (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the wiring harness channel mounting bolts on the body.

AIR CONDITIONING

- Fill the refrigerant circuit (see Refrigerant circuit: Draining - Filling) (MR 392, 62A, Air conditioning).

READ NEXT:

K9K, and JH3 or JR5 - K9K, and 772, and TL4

K9K, and JH3 or JR5 - K9K, and 772, and TL4

REMOVAL

I - REMOVAL PREPARATION OPERATION

Position the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 392, 02A, Lifting equipment).

WARNING

During this operation, secure the ve

D4F, and 740 or 742 or 764

D4F, and 740 or 742 or 764

REMOVAL

I - REMOVAL PREPARATION OPERATION

Position the vehicle on a two-post lift (see Vehicle: Towing and

lifting).

IMPORTANT

During this operation, secure the vehicle to the

lift with a strap

M4R, and DP0

M4R, and DP0

REMOVAL

I - REMOVAL PREPARATION OPERATION

Position the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 392, 02A, Lifting equipment).

IMPORTANT

During this operation, secure the

SEE MORE:

Sunroof sun visors: Removal - Refitting

Sunroof sun visors: Removal - Refitting

PANORAMIC SUNROOF

IMPORTANT

Before working on or near a safety system component;

make sure that the airbag computer is

locked using the Diagnostic tool. When this

function is activated, all the triggering lines are

inhibited and the airbag warning light on the

instrument panel is continuously lit (

Oil pump: Removal -

Refitting

Oil pump: Removal -

Refitting

D4F, and 740 or 742 or 764

REMOVAL

I - REMOVAL PREPARATION OPERATION

Position the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 392, 02A, Lifting equipment).

Disconnect the battery (see Battery: Removal - Refitting)

(MR 392, 80A, Battery).

Remove:

the dipstick,

the engi

© 2016-2026 Copyright Renault Clio Owners Club