Renault Clio: Brake servo non-return valve: Removal - Refitting

LEFT-HAND DRIVE

REMOVAL

I - REMOVAL PREPARATION OPERATION

K4J or K4M or K9K

- Remove the engine cover.

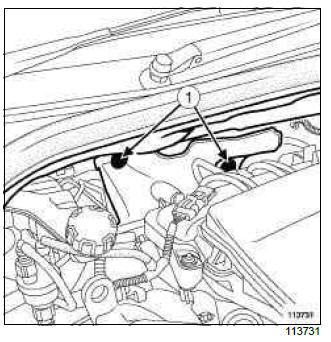

II - OPERATION FOR REMOVAL OF PART CONCERNED

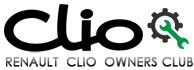

- Disconnect the non-return valve (1) at the servo.

- Pull and turn the non-return valve to release it from the rubber sealing washer.

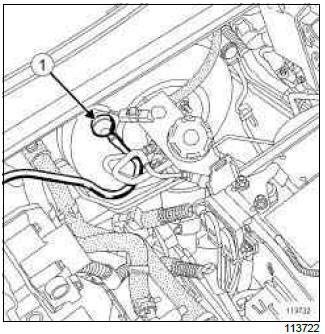

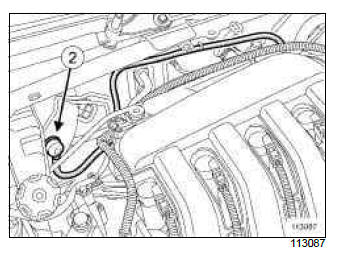

K9K

- Disconnect the non-return valve (2) at the vacuum pump.

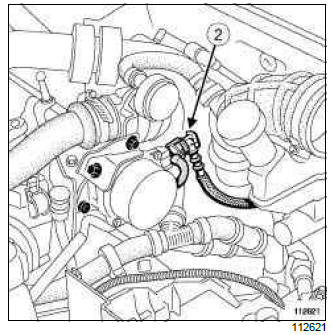

K4J or K4M

Note: Do not damage the vacuum tube on the plenum chamber. If it is damaged, the plenum chamber will have to be replaced.

- Disconnect the non-return valve (3) at the plenum chamber.

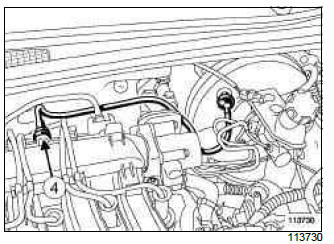

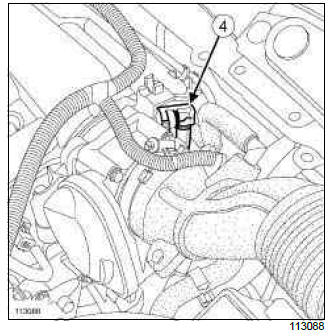

D4F

Note: Do not damage the vacuum tube on the plenum chamber. If it is damaged, the plenum chamber will have to be replaced.

- Disconnect the non-return valve (4) at the inlet manifold.

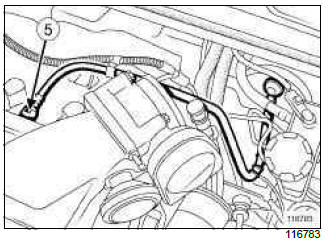

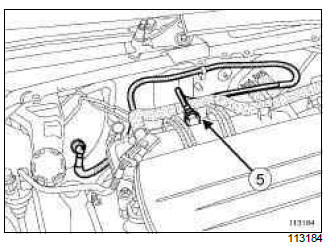

F4R

Note: Do not damage the vacuum tube on the plenum chamber. If it is damaged, the plenum chamber will have to be replaced.

- Disconnect the non-return valve (5) at the plenum chamber.

- Remove the non-return valve.

REFITTING

I - REFITTING PREPARATIONS OPERATION

- Check the condition of the sealing washer and the non-return valve.

- Replace any faulty parts.

II - REFITTING OPERATION FOR PART CONCERNED

- Refit the non-return valve.

K9K

- Connect the non-return valve at the vacuum pump,

D4F or F4R or K4J or K4M

- Connect the non-return valve at the inlet manifold.

- Connect the non-return valve on the servo,

III - FINAL OPERATION.

K4J or K4M or K9K

- Refit the engine cover.

RIGHT-HAND DRIVE

REMOVAL

I - REMOVAL PREPARATION OPERATION

K4J or K4M or K9K

- Remove the engine cover.

- Remove the soundproofing retaining clips (1).

- lift away the upper section of the soundproofing.

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Disconnect the non-return valve (2) at the servo,

- Pull and turn the non-return valve to release it from the rubber sealing washer.

K9K

- Disconnect the non-return valve (3) at the vacuum pump,

K4J or K4M

Note: Do not damage the vacuum tube on the plenum chamber. If it is damaged, the plenum chamber will have to be replaced.

- Disconnect the non-return valve (4) at the plenum chamber.

D4F

Note: Do not damage the vacuum tube on the plenum chamber. If it is damaged, the plenum chamber will have to be replaced.

- Disconnect the non-return valve (5) at the inlet manifold.

- Remove the non-return valve.

REFITTING

I - REFITTING PREPARATION OPERATION

- Check the condition of the rubber sealing washer and the non-return valve.

- Replace any faulty parts.

II - REFITTING OPERATION FOR PART CONCERNED

- Refit the non-return valve.

K9K

- Connect the non-return valve at the vacuum pump,

D4F or K4J or K4M

- Connect the non-return valve at the inlet manifold.

- Connect the non-return valve at the servo,

III - FINAL OPERATION

- Refit the upper section of the soundproofing.

- Refit the soundproofing retaining clips

K4J or K4M or K9K

- Refit the engine cover.