Renault Clio: Coolant temperature sensor: Removal - Refitting

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Disconnect the battery (see Battery: Removal - Refitting) (80A, Battery).

- Remove:

- the engine cover,

- the air intake sleeve.

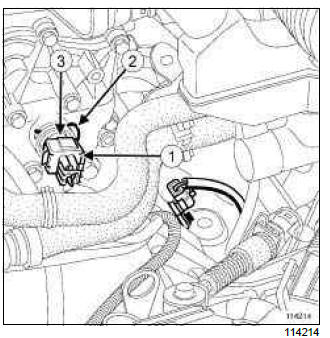

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Disconnect the coolant temperature sensor connector (1).

- Unclip the retaining clip (2) on the coolant temperature sensor.

- Remove the coolant temperature sensor (3).

REFITTING

I - REFITTING PREPARATION OPERATION

- Always replace the coolant temperature sensor O-ring.

II - REFITTING OPERATION FOR PART CONCERNED

- Refit the coolant temperature sensor.

- Secure the coolant temperature sensor with the retaining clip.

- Connect the coolant temperature sensor connector.

III - FINAL OPERATION

- Fill the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16) (MR 392, 19A, Cooling).

- Connect the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

- Bleed the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16) (MR 392, 19A, Cooling).

- Refit:

- the air intake sleeve,

- the engine cover.

K9K

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Remove:

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the engine cover.

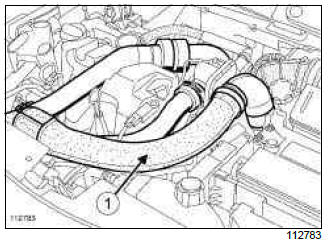

- Remove:

- the air filter inlet air pipe (1),

- the battery tray (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the air filter unit (see 12A, Fuel mixture, Air filter unit: Removal - Refitting, 12A-17),

- the engine undertray.

- Drain the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16) (MR 392, 19A, Cooling).

- Clean the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16) (MR 392, 19A, Cooling).

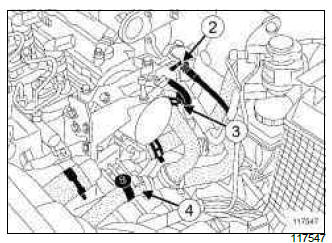

- Disconnect the vacuum pipe (2) from the vacuum pump.

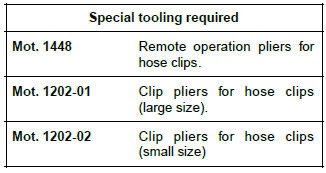

- Remove the clip (3) from the coolant hose using the (Mot. 1448) or (Mot. 1202-01) or (Mot. 1202-02).

- Disconnect the coolant hose.

- Unclip the coolant hose (4).

II - OPERATION FOR REMOVAL OF PART CONCERNED

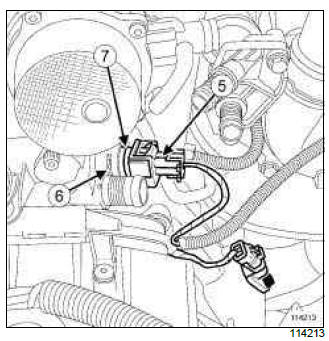

- Disconnect the coolant temperature sensor connector (5).

- Remove:

- the coolant temperature sensor retaining clip (6),

- the coolant temperature sensor (7),

- the coolant temperature sensor O-ring.

REFITTING

I - REFITTING PREPARATION OPERATION

- The coolant temperature sensor O-ring must always be replaced.

- Connect the coolant temperature sensor connector.

II - REFITTING OPERATION FOR PART CONCERNED

- Refit:

- the coolant temperature sensor,

- the coolant temperature sensor retaining clip.

III - FINAL OPERATION

- Connect the coolant hose.

- Fit the coolant hose clip using the (Mot. 1448) or (Mot. 1202-01) or (Mot. 1202-02).

- Clip the coolant hose.

- Connect the vacuum pipe to the vacuum pump.

- Refit:

- the engine undertray,

- the air filter unit (see 12A, Fuel mixture, Air filter unit: Removal - Refitting, 12A-17),

- the battery tray (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the air filter inlet air pipe,

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- Perform the following operations:

- fill the engine cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A- 16) (MR 392, 19A, Cooling),

- bleed the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16) (MR 392, 19A, Cooling).

- Refit the engine cover.

D4F, and 740 or 742 or 764

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Disconnect the battery (see Battery: Removal - Refitting).

- Remove the air filter unit (see 12A, Fuel mixture, Air filter unit: Removal - Refitting, 12A-17) (80A, Battery).

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Disconnect the coolant temperature sensor connector.

- Remove the coolant temperature sensor.

REFITTING

I - REFITTING PREPARATION OPERATION

- Always replace the coolant temperature sensor O-ring.

II - REFITTING OPERATION FOR PART CONCERNED

- Refit:

- the coolant temperature sensor O-ring,

- the coolant temperature sensor.

- Connect the coolant temperature sensor connector.

III - FINAL OPERATION

- Refit the air filter unit (see 12A, Fuel mixture, Air filter unit: Removal - Refitting, 12A-17).

- Fill the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16) (MR 392, 19A, Cooling).

- Connect the battery (see Battery: Removal - Refitting) (80A, Battery).

- Bleed the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16) (MR 392, 19A, Cooling).

F4R

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Disconnect the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

- Remove the engine undertray.

- Perform the following operations:

- drain the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16),

- flush out the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A- 16).

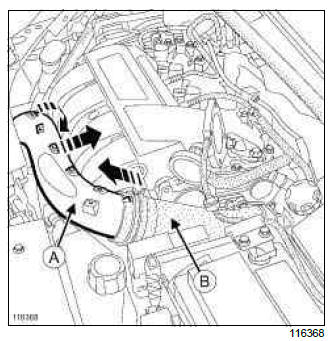

- Remove the air inlet duct (A) :

- unclip it from the front end panel,

- turn it and disconnect it.

- Disconnect the duct (B) :

- air resonator side,

- air filter unit side.

- Remove:

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the battery tray (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery).

- Unclip the breather pipe from the gearbox.

II - OPERATION FOR REMOVAL OF PART CONCERNED

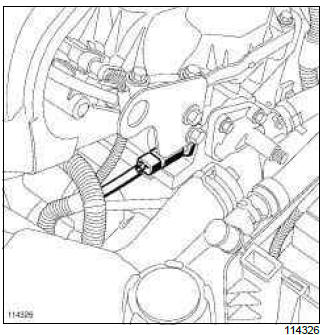

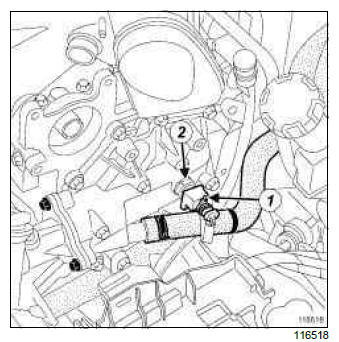

- Disconnect the coolant temperature sensor connector (1).

- Remove the coolant temperature sensor (2).

REFITTING

I - REFITTING OPERATION FOR PART CONCERNED

- Refit the coolant temperature sensor fitted with a new seal.

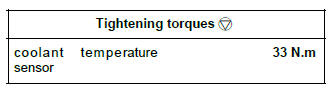

- Tighten to torque the coolant temperature sensor (33 N.m).

- Connect the coolant temperature sensor connector.

II - FINAL OPERATION

- Clip the breather pipe to the gearbox.

- Connect the duct (B) :

- to air filter unit,

- to the air resonator.

- Refit:

- the air inlet duct (A),

- the battery tray (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

- Connect the battery ( (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

- Perform the following operations:

- fill the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16) (MR 392, 19A, Cooling),

- bleed the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16) (MR 392, 19A, Cooling).

- Check that there are no leaks.

- Refit the engine undertray.

D4F, and 784 or 786

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Disconnect the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

- Remove:

- the engine undertray,

- the engine cover,

- the throttle valve (see 12A, Fuel mixture, Throttle valve: Removal - Refitting, 12A-33).

- Drain the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16) (MR 392, 19A, Cooling).

II - OPERATION FOR REMOVAL OF PART CONCERNED

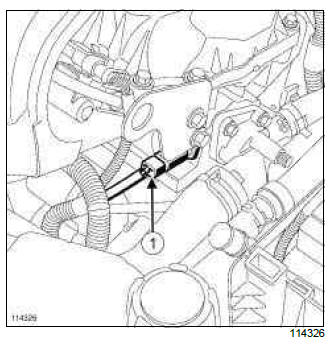

- Disconnect the coolant temperature sensor connector (1).

- Remove the coolant temperature sensor.

- Remove:

- the coolant temperature sensor,

- the coolant temperature sensor O-ring.

REFITTING

I - REFITTING PREPARATION OPERATION

- Always replace the coolant temperature sensor O-ring.

II - REFITTING OPERATION FOR PART CONCERNED

- Refit:

- the coolant temperature sensor O-ring,

- the coolant temperature sensor.

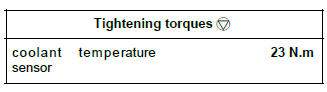

- Torque tighten the coolant temperature sensor (23 N.m).

- Connect the coolant temperature sensor connector.

III - FINAL OPERATION

- Refit:

- the throttle valve (see 12A, Fuel mixture, Throttle valve: Removal - Refitting, 12A-33),

- the engine cover.

- Connect the battery (see ) (MR 392, 80A, Battery).

- Fill and bleed the cooling system (see 19A, Cooling, Cooling system: Draining - Refilling, 19A-16) (MR 392, 19A, Cooling).

- Refit the engine undertray.