Renault Clio: Diesel injection computer: Configuration

K9K, and 750 or 752 or 764 or 766 or 768

- To configure the computer, (see MR 394 Fault finding, Diesel Injection, Configuration and programming).

Diesel injection computer: Removal - Refitting

K9K

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Remove:

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the battery heat shield,

- the air filter box (see 12A, Fuel mixture, Air filter unit: Removal - Refitting, 12A-17).

II - REMOVAL OF PART CONCERNED

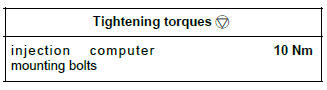

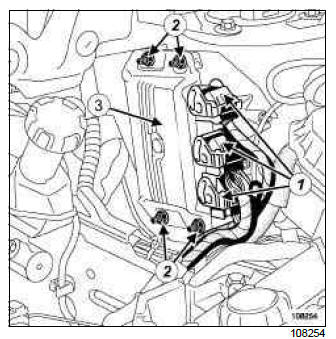

- Disconnect the three connectors (1) from the injection computer.

- Remove:

- the injection computer mounting bolts (2),

- the injection computer (3).

REFITTING

I - REFITTING PART CONCERNED

- Refit the injection computer.

- Torque tighten the injection computer mounting bolts (10 Nm).

II - FINAL OPERATION.

- Connect the injection computer connectors.

- Refit the air filter box (see 12A, Fuel mixture, Air filter unit: Removal - Refitting, 12A-17).

- Refit the battery heat shield,

- Refit the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

Flow regulation solenoid valve: Removal - Refitting

K9K, and 764 or 772

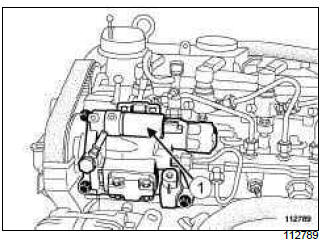

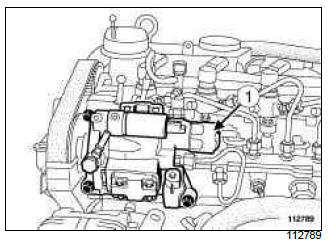

- The flow regulation solenoid valve (1) is integral with the high pressure pump.

- Replace the " high pressure pump - flow regulation solenoid valve " assembly in the event of a fault in the flow regulation solenoid valve (see 13B, Diesel injection, High pressure pump: Removal - Refitting, 13B-23).

Pressure regulation solenoid valve: Removal - Refitting

K9K, and 764 or 772

- The pressure regulation solenoid valve (1) is integral with the high pressure pump.

- Replace the " high pressure pump - pressure solenoid valve " assembly in the event of a fault in the pressure regulation solenoid valve (see 13B, Diesel injection, High pressure pump: Removal - Refitting, 13B-23).

READ NEXT:

High pressure pump leak flow: Check

High pressure pump leak flow: Check

K9K, and 764 or 772

Disconnect the battery (see Battery: Removal - Refitting)

(MR 392, 80A, Battery).

Disconnect the inlet pressure sensor (1).

Remove:

the air duct (2) between the air fil

High pressure pump: Removal - Refitting

High pressure pump: Removal - Refitting

K9K, and 764 or 772

WARNING

Before starting work on the vehicle, obtain:

a new plug kit (PART NO. 77 01 476 857),

cleaning cloths (PART NO. 77 11 211 707),

cleaning product (PART NO. 77 11 224 18

Flow actuator: Removal - Refitting

Flow actuator: Removal - Refitting

K9K, and 750 or 752 or 766 or 768

IMPORTANT

Before carrying out any work on the injection system,

check using the Diagnostic tool :

that the injector rail is not under pressure,

that the fuel temp

SEE MORE:

Flow actuator: Removal - Refitting

Flow actuator: Removal - Refitting

K9K, and 750 or 752 or 766 or 768

IMPORTANT

Before carrying out any work on the injection system,

check using the Diagnostic tool :

that the injector rail is not under pressure,

that the fuel temperature is not too high.

It is essential to respect the safety and cleanliness

advice whenever work

Front seat height adjustment: Removal - Refitting

Front seat height adjustment: Removal - Refitting

FRONT SEAT TYPE 02 or FRONT SEAT TYPE 03 or FRONT SEAT TYPE 05, and

WITHOUT SPORT SEATS, and

DOCUMENTATION PHASE 2

IMPORTANT

Before beginning work on any component of the

safety system, it is essential to lock the airbag computer

using the Diagnostic tool (see Airbag and

pretensioners: Precautions

© 2016-2026 Copyright Renault Clio Owners Club