Renault Clio: Front side member, centre section: General description

IMPORTANT

Use a repair bench to ensure the positioning of the points and the geometry of the axle assemblies.

Note: The information contained in the following describes the general repair procedure for all vehicles having the same design for this part.

Before reading the following general information, make sure that there are no special notes associated with the vehicle. These special notes are specified if necessary in other parts of the sub-section dealing with the component.

Note: For a detailed description of a particular connection, see MR 400.

DESIGN OF THE STRUCTURAL COMPONENT

This is a basic part; its only function is that of front side member, centre section.

WARNING

If the mating faces of the parts to be welded are not accessible, make EGW plug welds to replace the original resistance welds (see MR 400).

Front side member, centre section: Description

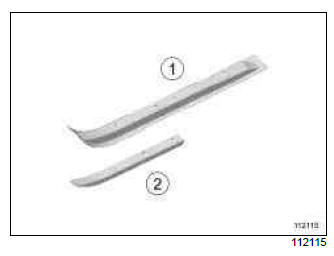

There is only one way of replacing this part:

- Complete replacement:

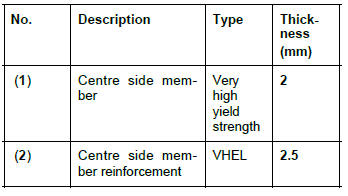

I - COMPOSITION OF THE SPARE PART

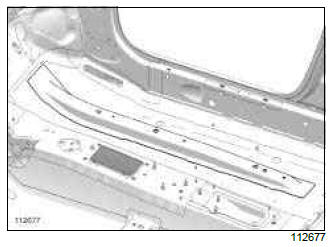

II - PART FITTED

WARNING

- To avoid damaging the vehicle's electrical and electronic components, be sure to disconnect the earths of any wiring near the weld zone.

- The welding machine earth must be placed as close as possible to the weld zone.

IMPORTANT

For welded connections in three thicknesses, the spot welds on the part replaced should be made in the same place as for the original joint to retain its mechanical properties.