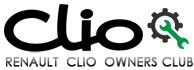

Renault Clio: Front right-hand driveshaft gaiter, gearbox side: Removal - Refitting

DP0 or JH3 or JR5 or TL4

- Deflector

- Propeller shaft

- Driveshaft yoke sleeve

- Spider

- RC gaiter

- Tightening clip

- Lock ring

- Tightening ring

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Disconnect the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

- Remove the front right-hand driveshaft (see 29A, Driveshafts, Front right-hand driveshaft: Removal - Refitting, 29A-9).

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Cut the ring (8) and the tightening clip (6) using cutting pliers or a metal saw, taking care not to damage the yoke sleeve.

- Push back the gaiter (5) to release the driveshaft yoke sleeve.

- Remove as much grease as possible.

WARNING

Never use thinners to clean the components.

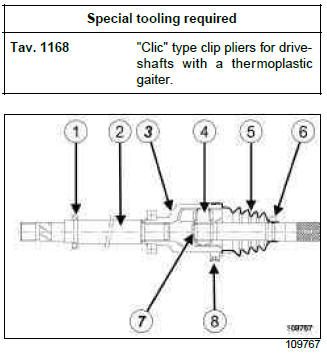

- Remove the driveshaft yoke sleeve (3).

Note:

- Since the driveshaft yoke sleeve does not have a stop tab, it can be removed without being forced.

- Do not remove the rollers from their respective bushings as the rollers and needles are matched and should never be interchanged.

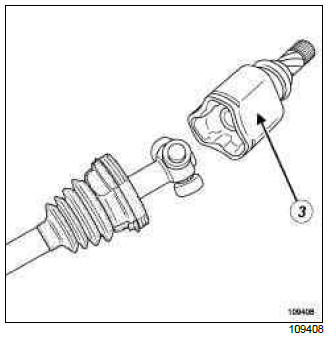

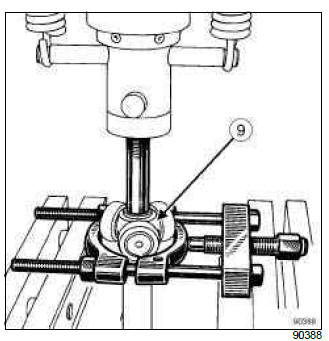

- Remove the lock ring (7) using the tool.

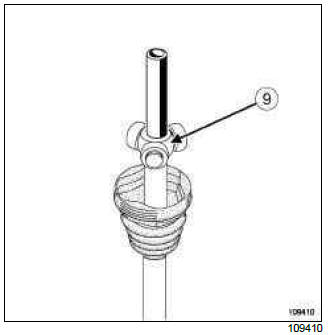

- Extract the spider (9), using a press and a releasing type extractor.

Note: Mark the position of the spider before extracting it.

- Remove the propeller shaft gaiter.

REFITTING

I - REFITTING OPERATION FOR PART CONCERNED

- Fit the small tightening clip (6) to the propeller shaft.

- Slightly lubricate the propeller shaft to facilitate fitting the gaiter.

- Refit the propeller shaft gaiter.

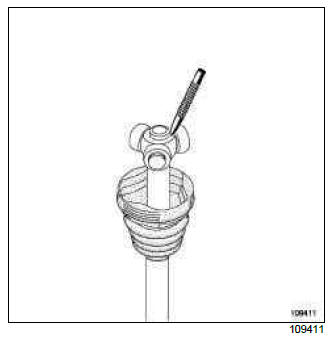

- Refit the spider (9) in the position marked during removal.

- Refit the retaining lock ring (7) or crimp at three

points at 120

READ NEXT:

Front left-hand driveshaft gaiter, gearbox side: Removal - Refitting

Front left-hand driveshaft gaiter, gearbox side: Removal - Refitting

DP0 or JH3 or JR5 or TL4

Tightening clip

Tightening ring

Cup

Driveshaft yoke sleeve

Deflector

Propeller shaft

RC gaiter

Spider

Lock ring

Spring

REMOVAL

I - REMOVAL PREPARATION OPERATION

Chassis

Chassis

The Renault Clio IV (2014-2019) features a well-engineered chassis that contributes to its handling, stability, and overall driving dynamics. The chassis is designed to provide a balanced and controll

SEE MORE:

3rd brake light: Removal - Refitting

3rd brake light: Removal - Refitting

B85 or C85 or S85

REMOVAL

OPERATION FOR REMOVAL OF PART

CONCERNED

Remove the blanking covers (1).

Insert a screwdriver in the openings to move the clips (2).

Apply pressure to the clips (2) to unclip the high level

brake light.

Partially remove the raised brake light using a flat-blade

Tyre Pressure Monitor

Tyre Pressure Monitor

Tyre pressure monitor: List and location of components

TYRE PRESSURE SENSOR

The system consists of:

four pressure sensors (1) built into the valves (one per

wheel); the sensors transmit a radio signal,

a computer (2) which collects, decodes and processes

sensor signals, and then determines whi

© 2016-2026 Copyright Renault Clio Owners Club