Renault Clio: Actuator module: Removal - Refitting

K9K, and JA5

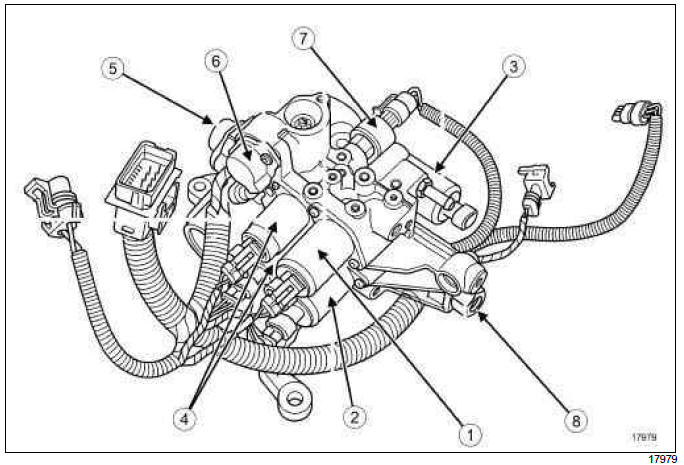

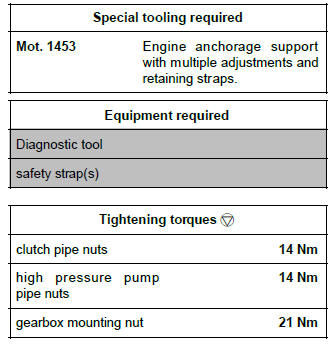

(1) Clutch solenoid valve

(2) Gear engagement solenoid

valve

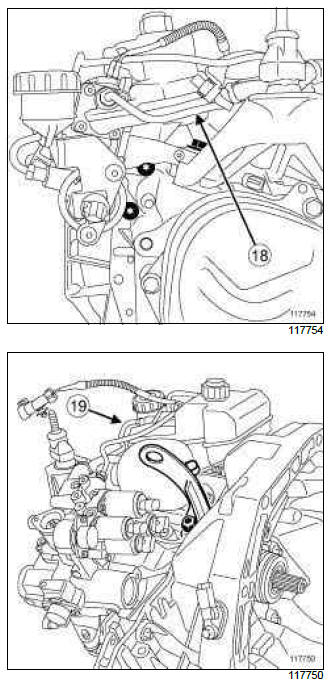

(18) Gear engagement solenoid

valve

(4) Selection solenoid valve

(5) Engagement sensor

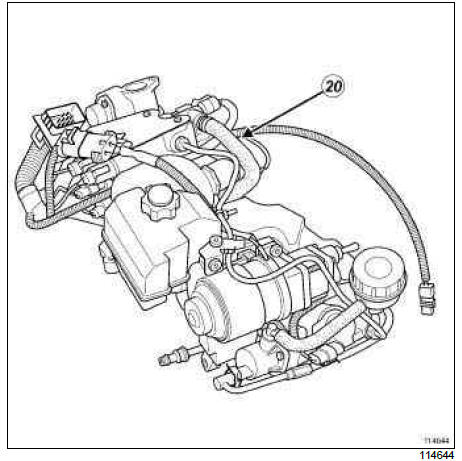

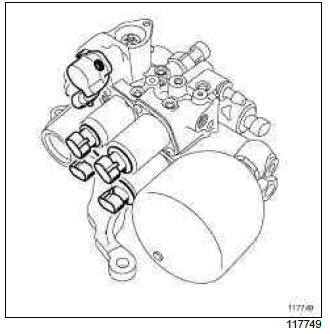

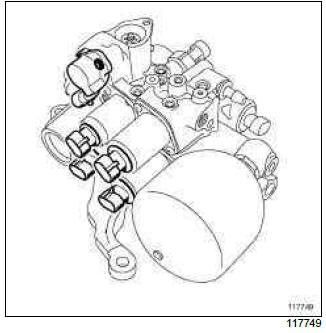

(20) Gear selection sensor

(7) Solenoid valve unit pressure

sensor

(8) High pressure filter

REMOVAL

I - REMOVAL PREPARATION OPERATION

IMPORTANT

Before any operation on the sequential system, discharge the accumulator using the Diagnostic tool.

- To discharge the accumulator, run command

" Discharge pressure accumulator " AC081.

To confirm the pressure drop, read the " Hydraulic pressure " parameter for the resulting value.

If there is still pressure in the accumulator, re-run the " Discharge pressure accumulator " command until the pressure is negligible and will not pose a risk when the high pressure pipes are removed.

The pressure reading must be close to zero.

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Remove:

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the battery tray (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the air filter unit (see Air filter unit: Removal - Refitting) (MR 392, 12A, Fuel mixture).

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the scoop under the scuttle panel grille (see Scoop under the scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the diesel injection computer (see Diesel injection computer: Removal - Refitting) (MR 392, 13B, Diesel injection),

- the wiring harness nut under the injection computer.

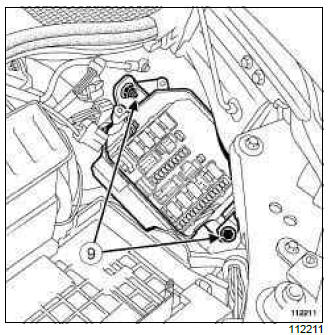

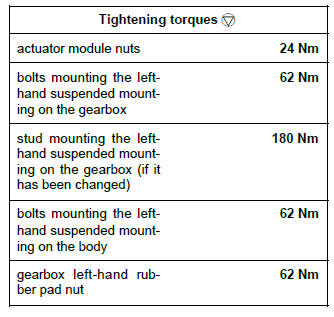

- Remove the Protection and Switching Unit (9).

- Remove:

- the Protection and Switching Unit,

- the wiring harness under the injection computer.

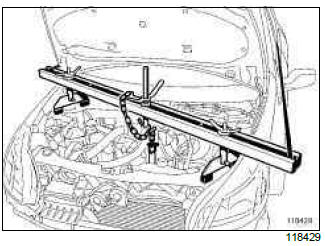

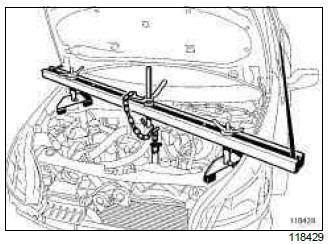

- Fit the (Mot. 1453) with a safety strap(s).

- Remove:

- the front left-hand wheel (see Wheel: Removal - Refitting) (MR 392, 35A, Wheels and tyres),

- the front left-hand wheel arch liner (see Front wheel arch liner: Removal - Refitting) (MR 393, 55A, Exterior protection).

- the side stiffener bolts on the left-hand side of the vehicle,

- the side stiffener on the left-hand side of the vehicle,

- the engine undertray.

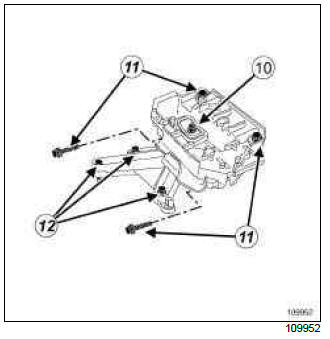

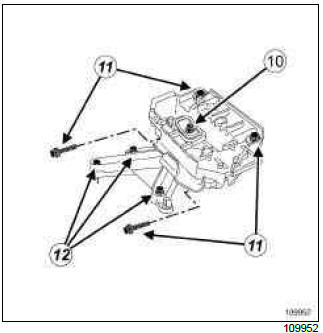

- Remove:

- the nut (10) from the gearbox left-hand rubber pad,

- the bolts (11) from the left-hand suspended mounting on the body,

- the left-hand suspended mounting from the body,

- the bolts (12) from the gearbox left-hand suspended mounting,

- the gearbox left-hand suspended mounting.

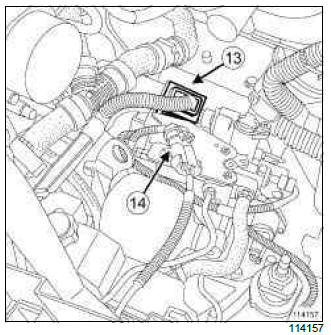

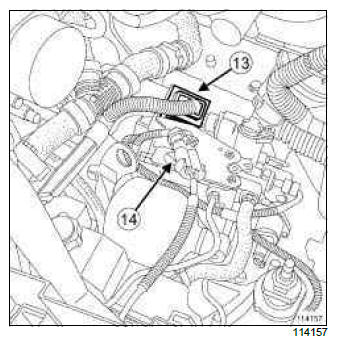

- Disconnect:

- the connector from the actuator module (13),

- the connector from the pump assembly (14).

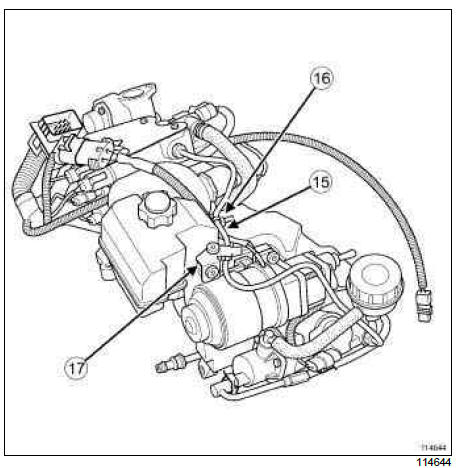

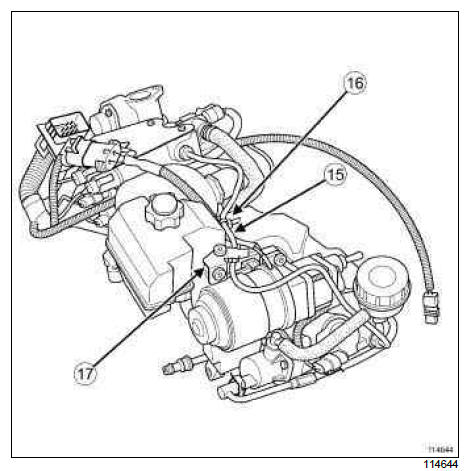

- Remove:

- the clutch pipe (15),

- the clutch pipe bracket (16).

- Cut the clip on the clutch pipe (17).

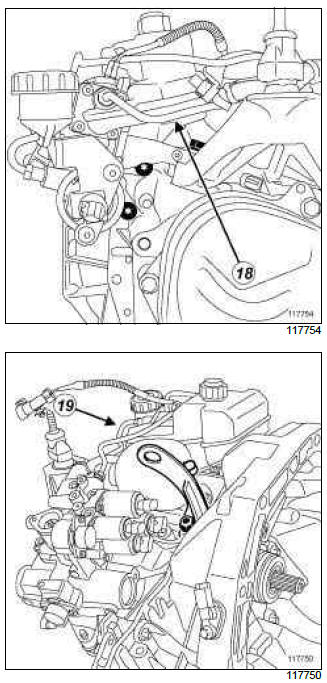

- Remove the high pressure pump pipes (18) and (20).

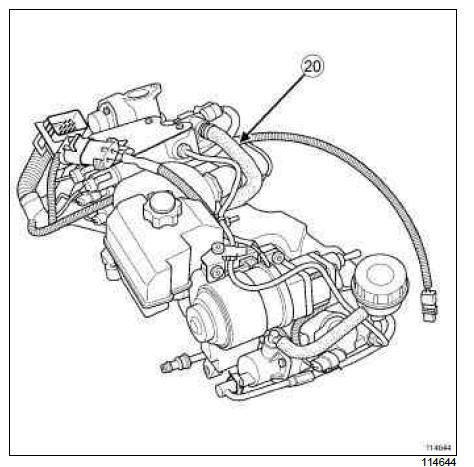

- Remove the low pressure pump pipe (20).

Note: To avoid any sequential gearbox malfunction, mark the routing for the solenoid valve and sensor wiring on the actuator module.

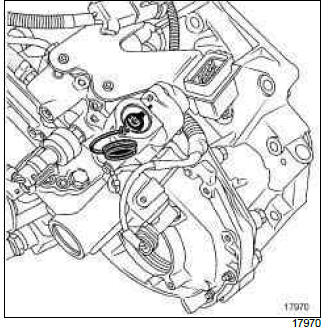

II - OPERATION FOR REMOVAL OF PART CONCERNED

Note: The actuator module can be removed or refitted with the pressure accumulator in place.

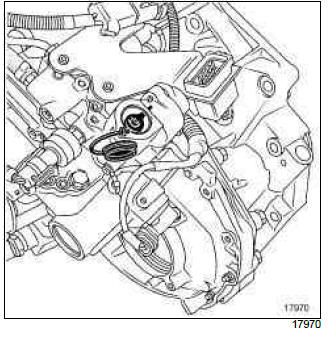

- Remove:

- the lifting eye on the gearbox,

- the nuts from the actuator module.

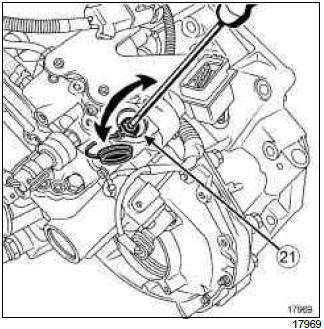

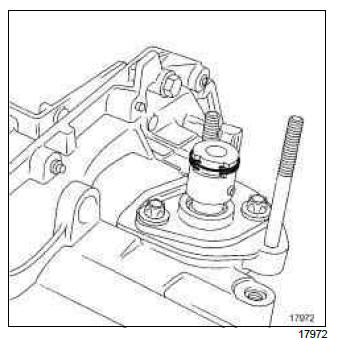

Actuator module

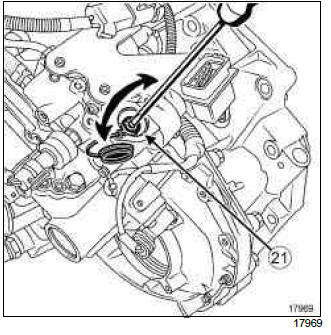

Selector shaft locked

Selector shaft unlocked

- Unlock the gear selector shaft (21) by turning the shaft by a quarter of a turn using a screwdriver.

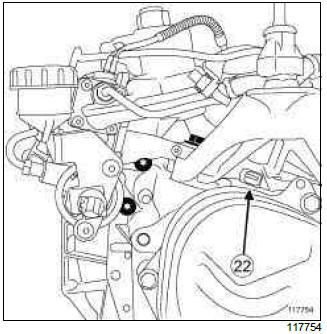

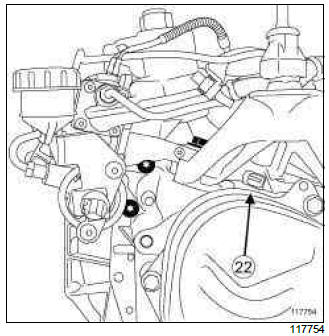

- Disconnect the sequential gearbox sensor connector (22).

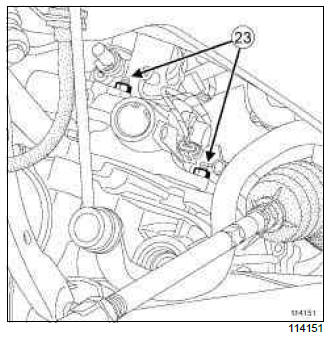

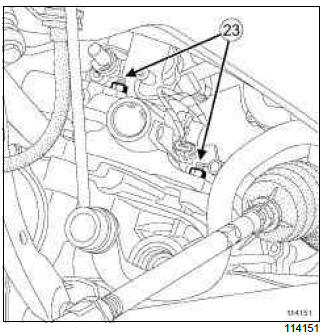

- Remove the nuts (23) from the electro-hydraulic unit.

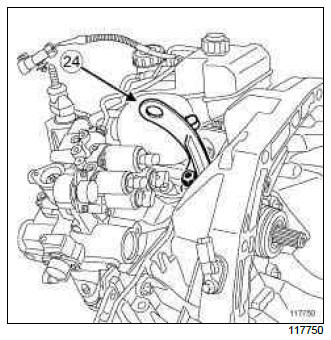

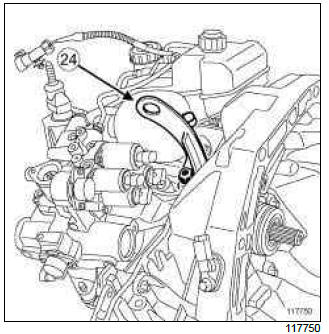

- Remove:

- the lifting eye nut on the actuator module,

- the lifting eye (24) on the actuator module,

- the actuator module.

I - REFITTING PREPARATIONS OPERATION

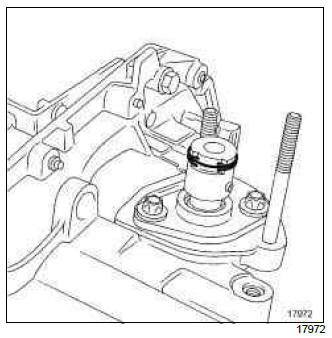

- Check that the two half-moons are positioned correctly.

- Position the two half-moons and the circlips in the selector shaft neck.

- Coat the two half-moons and the selector finger with MOLYCOTE.

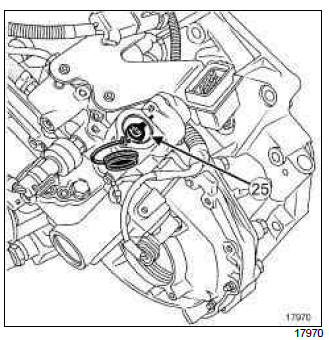

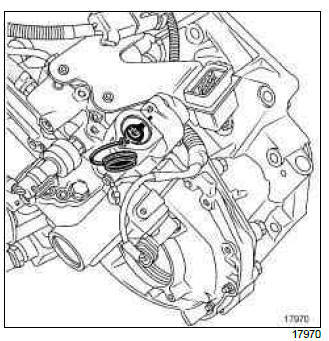

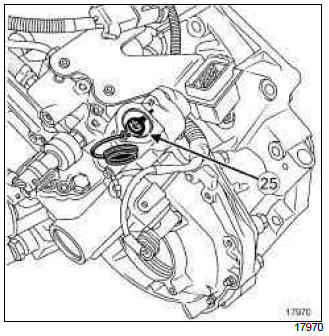

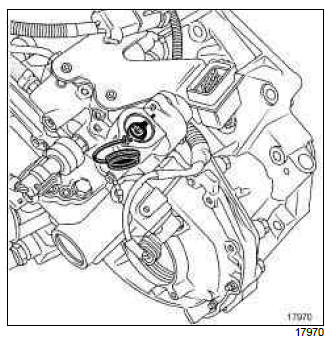

- Lock the selector shaft (25).

- Position the flat seal.

II - REFITTING OPERATION FOR PART CONCERNED

- Using a screwdriver, press on the selector shaft to clip it onto the actuator module.

- Refit:

- the low pressure pump pipe,

- the high pressure pump pipe,

- the clutch pipe,

- the clutch pipe bracket,

- a new clip on the clutch pipe,

- the nuts from the actuator module.

- Without tightening, fit:

- the clutch pipe nuts,

- the high pressure pump pipe nuts.

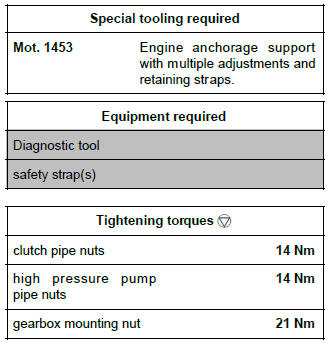

- Torque tighten:

- the clutch pipe nuts (14 Nm),

- the high pressure pump pipe nuts (14 Nm),

- the gearbox mounting nut (21 Nm),

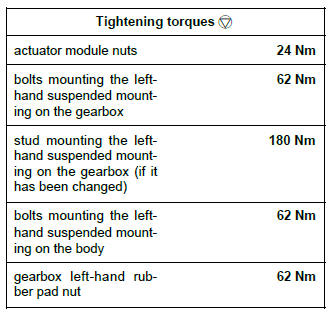

- the actuator module nuts (24 Nm).

- Connect the sequential gearbox speed sensor connector.

- Remove the (Mot. 1453) and the safety strap(s).

- Reposition the left-hand suspended mounting on the gearbox.

- Refit the bolts mounting the left-hand suspended mounting on the gearbox.

- Torque tighten:

- the bolts mounting the left-hand suspended mounting on the gearbox (62 Nm),

- the stud mounting the left-hand suspended mounting on the gearbox (if it has been changed) (180 Nm)

- Reposition the left-hand suspended mounting on the body.

- Refit the left-hand suspended mounting bolts on the body.

- Torque tighten:

- the bolts mounting the left-hand suspended mounting on the body (62 Nm),

- the gearbox left-hand rubber pad nut (62 Nm).

- Refit:

- the side stiffener bolts on the left-hand side of the vehicle,

- the side stiffener on the left-hand side of the vehicle,

- the front left-hand wheel arch liner (see Front wheel arch liner: Removal - Refitting) (MR 393, 55A, Exterior protection).

- the engine undertray,

- the Protection and Switching Unit,

- the diesel injection computer (see Diesel injection computer: Removal - Refitting) (MR 392, 13B, Diesel injection),

- the scoop under the scuttle panel grille (see Scoop under the scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the air filter unit (see Air filter unit: Removal - Refitting) (MR 392, 12A, Fuel mixture),

- the battery tray (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the front left-hand wheel (see Wheel: Removal - Refitting) (MR 392, 35A, Wheels and tyres),

III - FINAL OPERATION.

- Carry out the necessary programming (see Fault finding - Replacement of components) (MR 394, 21B, Sequential gearbox).

WARNING

After the accumulator has been fully filled (15 seconds after the ignition has been switched on): the oil is at the MIN mark.

D4F, and JA3

- Clutch solenoid valve

- Gear engagement solenoid valve

- Gear engagement solenoid valve

- Selection solenoid valve

- Engagement sensor

- Gear selection sensor

- Solenoid valve unit pressure sensor

- High pressure filter

REMOVAL

I - REMOVAL PREPARATION OPERATION

IMPORTANT

Before any operation on the sequential system, discharge the accumulator using the Diagnostic tool.

- To discharge the accumulator, run command

" Discharge pressure accumulator " AC081.

To confirm the pressure drop, read the " Hydraulic pressure " parameter for the resulting value.

If there is still pressure in the accumulator, re-run the " Discharge pressure accumulator " command until the pressure is negligible and will not pose a risk when the high pressure pipes are removed.

The pressure reading must be close to zero.

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Remove:

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the battery tray (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the air filter unit (see Air filter unit: Removal - Refitting) (MR 392, 12A, Fuel mixture).

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the scoop under the scuttle panel grille (see Scoop under the scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the diesel injection computer (see Diesel injection computer: Removal - Refitting) (MR 392, 13B, Diesel injection),

- the wiring harness nut under the injection computer.

- Remove the Protection and Switching Unit bolts (9).

- Remove:

- the Protection and Switching Unit,

- the wiring harness under the injection computer.

- Fit the (Mot. 1453) with a safety strap(s).

- Remove:

- the front left-hand wheel (see Wheel: Removal - Refitting) (MR 392, 35A, Wheels and tyres),

- the front left-hand wheel arch liner (see Front wheel arch liner: Removal - Refitting) (MR 393, 55A, Exterior protection).

- the side stiffener bolts on the left-hand side of the vehicle,

- the side stiffener on the left-hand side of the vehicle,

- the engine undertray.

- Remove:

- the nut (10) from the gearbox left-hand rubber pad,

- the bolts (11) from the left-hand suspended mounting on the body,

- the left-hand suspended mounting from the body,

- the bolts (12) from the gearbox left-hand suspended mounting,

- the gearbox left-hand suspended mounting.

- Disconnect:

- the connector from the actuator module (13),

- the connector from the pump assembly (14).

- Remove:

- the clutch pipe (15),

- the clutch pipe bracket (16).

- Cut the clip on the clutch pipe (17).

- Remove the high pressure pump pipes (18) and (19)

- Remove the low pressure pump pipe (20).

Note: To avoid any sequential gearbox malfunction, mark the routing for the solenoid valve and sensor wiring on the actuator module.

II - OPERATION FOR REMOVAL OF PART CONCERNED

Note: The actuator module can be removed or refitted with the pressure accumulator in place.

- Remove:

- the lifting eye on the gearbox,

- the nuts from the actuator module.

Actuator module

Selector shaft locked

Selector shaft unlocked

- Unlock the gear selector shaft by turning the shaft (21) by a quarter of a turn using a screwdriver.

- Disconnect the sequential gearbox speed sensor connector (22).

- Remove the nuts (23) from the electro-hydraulic unit.

- Remove:

- the lifting eye nut on the actuator module,

- the lifting eye (24) on the actuator module,

- the actuator module.

REFITTING

I - REFITTING PREPARATIONS OPERATION

- Check that the two half-moons are positioned correctly.

- Position the two half-moons and the circlips in the selector shaft neck.

- Coat the two half-moons and the selector finger with MOLYCOTE.

- Lock the selector shaft (25).

- Position the flat seal.

II - REFITTING OPERATION FOR PART CONCERNED

- Using a screwdriver, press on the selector shaft to clip it onto the actuator module.

- Refit:

- the low pressure pump pipe,

- the high pressure pump pipe,

- the clutch pipe,

- the clutch pipe bracket,

- a new clip on the clutch pipe,

- the nuts from the actuator module.

- Without tightening, fit:

- the clutch pipe nuts,

- the high pressure pump pipe nuts.

- Torque tighten:

- the clutch pipe nuts (14 Nm),

- the high pressure pump pipe nuts (14 Nm),

- the gearbox mounting nut (21 Nm),

- the actuator module nuts (24 Nm).

- Connect the sequential gearbox speed sensor connector.

- Remove the (Mot. 1453) and the safety strap(s).

- Reposition the left-hand suspended mounting on the gearbox.

- Refit the bolts mounting the left-hand suspended mounting on the gearbox.

- Torque tighten:

- the bolts mounting the left-hand suspended mounting on the gearbox (62 Nm),

- the stud mounting the left-hand suspended mounting on the gearbox (if it has been changed) (180 Nm)

- Reposition the left-hand suspended mounting on the body.

- Refit the left-hand suspended mounting bolts on the body.

- Torque tighten:

- the bolts mounting the left-hand suspended mounting on the body (62 Nm),

- the gearbox left-hand rubber pad nut (62 Nm).

- Refit:

- the side stiffener bolts on the left-hand side of the vehicle,

- the side stiffener on the left-hand side of the vehicle,

- the front left-hand wheel arch liner (see Front wheel arch liner: Removal - Refitting) (MR 393, 55A, Exterior protection).

- the engine undertray,

- the Protection and Switching Unit,

- the diesel injection computer (see Diesel injection computer: Removal - Refitting) (MR 392, 13B, Diesel injection),

- the scoop under the scuttle panel grille (see Scoop under the scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the air filter unit (see Air filter unit: Removal - Refitting) (MR 392, 12A, Fuel mixture),

- the battery tray (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the front left-hand wheel (see Wheel: Removal - Refitting) (MR 392, 35A, Wheels and tyres),

III - FINAL OPERATION.

- Carry out the necessary programming (see Fault finding - Replacement of components) (MR 394, 21B, Sequential gearbox).

WARNING

After the accumulator has been fully filled (15 seconds after the ignition has been switched on): the oil is at the MIN mark.